In today’s solar industry, project success is no longer just about securing Tier 1 panels or top-rated inverters. For large-scale solar projects, performance isn’t solely determined by installing the most efficient components. For ESCOs (Energy Service Companies) and developers working under performance contracts, component compatibility—how panels, inverters, storage, and monitoring systems integrate—can make or break ROI.

What Do We Mean by Component Compatibility?

Compatibility ensures that solar panels, inverters, racking, cabling, and monitoring systems operate as a unified system. It’s about electrical, mechanical, and operational alignment, not just buying “good” parts.

Where Compatibility Breaks Down (and Costs You Money)

- Inverter–Panel Mismatch

- Oversizing modules without proper inverter matching can lead to inverter clipping, lost energy that can’t be recovered.

- Undersizing creates stranded capacity.

- Racking & Module Alignment

- Poor racking fit can create shading, wind uplift issues, or even structural failure over time.

- Misaligned tilt angles can reduce energy generation by 2–5%.

- Connectors & Cabling

- Using different DC connectors (MC4 vs. non-MC4) can cause arcing and fire risks.

- Voltage mismatches add resistance losses, cutting efficiency.

- Monitoring & SCADA Integration

- Systems that don’t “talk” to each other result in blind spots for O&M teams, delaying fault detection and repair.

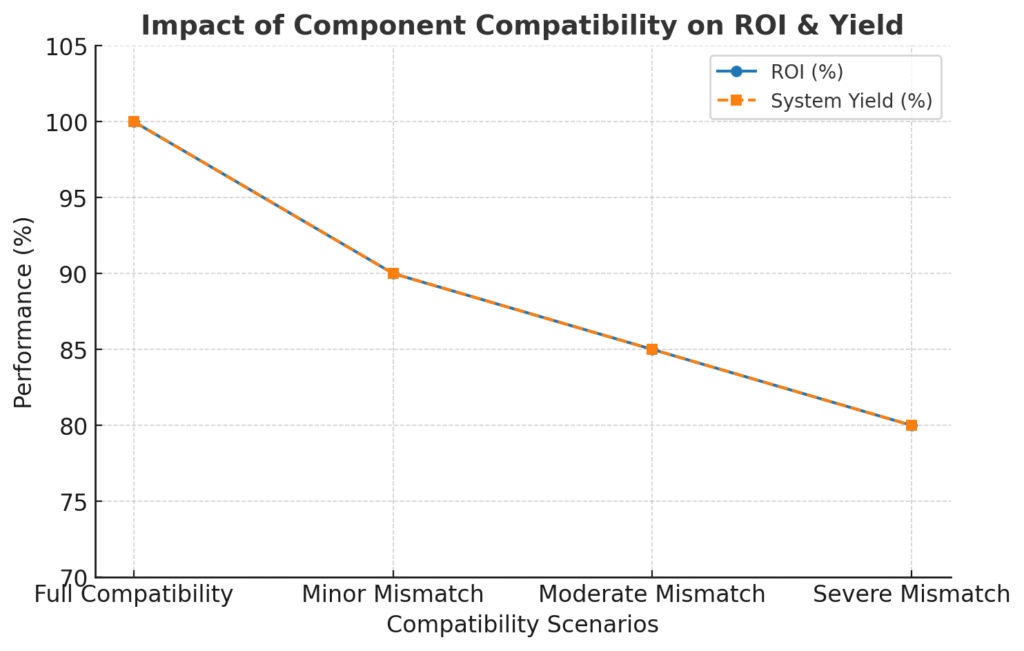

How Compatibility Impacts ROI & Yield

Think of a solar project like a high-performance engine. Every part needs to be tuned to the other. Even small inefficiencies add up over time.

Studies show that improper component pairing can reduce annual energy yield by 10–20%. That means lost revenue, longer payback periods, and frustrated stakeholders.

Here’s a simple breakdown of how compatibility affects ROI:

- Minor incompatibility (slight mismatch in sizing) → ~10% energy loss

- Moderate incompatibility (sub-optimal integration) → ~15% energy loss

- Severe incompatibility (improper pairing across core components) → ~20% energy loss

ROI & Yield Impact Chart

Small mismatches reduce energy yield and directly lower ROI over the project lifetime.

Why ESCOs and Developers Are Especially Vulnerable

While developers and EPCs face performance and financing risks, ESCOs are uniquely exposed because they guarantee cost savings to their clients. Any drop in energy performance directly eats into their margins.

Some of the most common challenges include:

- Inverter and Transformer Failures: Studies show these account for nearly two-thirds of total system losses in large projects often linked to integration issues.

- Extended Project Cycles: Large solar projects can already take 12 to 24 months from design to commissioning. Compatibility problems often add 60 to 120 days of delays, driving up financing costs and damaging ROI.

- O&M and Warranty Costs: Mismatched components void warranties and increase long-term maintenance burdens.

- Policy and Financing Pressures: In markets with strict clean energy targets and compliance requirements, compatibility failures can cause projects to miss performance guarantees, putting ESCOs at risk of financial penalties.

Compatibility: The Hidden Driver of Solar ROI

Most solar ROI conversations focus on module efficiency or PPA rates, but the truth is: system compatibility defines long-term value.

For ESCOs, this means ensuring:

- Solar + storage systems integrate with existing HVAC, lighting, and energy management systems.

- Inverters and transformers are properly matched to prevent system-wide losses.

- Monitoring platforms provide real-time, reliable data to meet client reporting obligations.

By addressing compatibility early in the design and procurement process, ESCOs and large-scale developers can reduce soft costs, protect performance guarantees, and deliver stable returns over decades.

Best Practices for Ensuring Compatibility

- Source from suppliers who provide end-to-end system design support.

- Use certified, tested combinations of modules, inverters, and racking.

- Demand bankability reports and third-party certifications.

- Prioritize partners with experience across multiple project types.

Key Takeaway

Component compatibility is not a “nice-to-have” it is the foundation of project bankability, long-term ROI, and system reliability. For EPCs, developers, and ESCOs, ensuring every component works seamlessly together is the difference between a system that merely runs and one that consistently delivers.

How Energy Solutions and Supplies Supports Compatibility

At Energy Solutions and Supplies, we’ve seen firsthand how a “compatibility-first” approach safeguards ROI for ESCOs, developers, and asset owners. From aligning inverter-string designs to vetting supply chains for long-term reliability, our role is to ensure your systems don’t just connect, they perform at scale. We bring:

- Proven methods for evaluating system-level compatibility before procurement.

- Experience mitigating integration risks across solar, storage, and efficiency technologies.

- A track record of helping ESCOs protect performance guarantees and accelerate payback timelines.

In today’s energy market, where every kilowatt-hour and every day of delay carries financial weight, prioritizing component compatibility is the most effective way to maximize ROI and maintain client trust.

Sources

- Solar Inverter Failures & Energy Loss – “Solar Inverter Failures Insights”

- Performance Degradation Rates – “How Extreme Weather and System Aging Affect the U.S. Photovoltaic Fleet”

- Soiling Loss Impact on PV Performance – IEA-PVPS Key Topics

- General Soiling Info – Wikipedia: Soiling (Solar Energy)

- System Availability & Downtime – PV Magazine: Understanding Solar Production Losses

- Component Failures and System Risk – MDPI Energies Journal

- Harmonics & Transformer Reliability – PAC World: Mitigating High-Order Harmonics